Every Lift Counts – Know Your Gear

Electric Chain Hoist vs Winch

Electric Chain Hoist vs Winch: Which Is Better for Your Stage Project?

1. Abstract:Comparing principles, construction, performance, and stage applications – including selection advice and maintenance points.

In stage rigging, electric chain hoists and winches each have distinct characteristics in design, performance, and application. This article compares them step by step — definitions, technical specs, use cases, industry standards, selection guidelines, maintenance, and common pitfalls — so you can make safer, faster decisions on equipment for touring, theatre, TV, concerts and fixed installations.

Audience:

• Non-technical decision makers (event organizers, venue managers, promoters) — quick, actionable guidance and a clear understanding of each device’s function and which equipment suits which scenario.

• Technical readers (stage rigging engineers, scenic contractors, rental technicians) — detailed technical points and standard references valuable for design, procurement, and inspection.

2. Core Conclusion: The Essentials in One Line

- Electric chain Hoist: excels at short-travel, high-frequency vertical lifts with precise positioning.

- Winch: excels at long-travel or horizontal pulling tasks requiring high pulling force.

Note: in this article “electric chain hoist” refers specifically to ring-chain (load-chain) entertainment hoists rather than drum/wire-rope hoists. This distinction maps to international standards: “EN 14492-2:2019 — Cranes: Power Driven Winches and Hoists, Part 2 — Power Driven Hoists” focuses on hoists, while “ASME B30.7 — Winches” covers drum-type winches.

3. Definitions and Quick Comparison (For Non-Experts)

3 1. What is an Electric chain Hoist?

- Definition: A vertically-hung lifting unit that uses a load chain running over a chain wheel and gearbox, driven by a motor (ring-chain hoist).

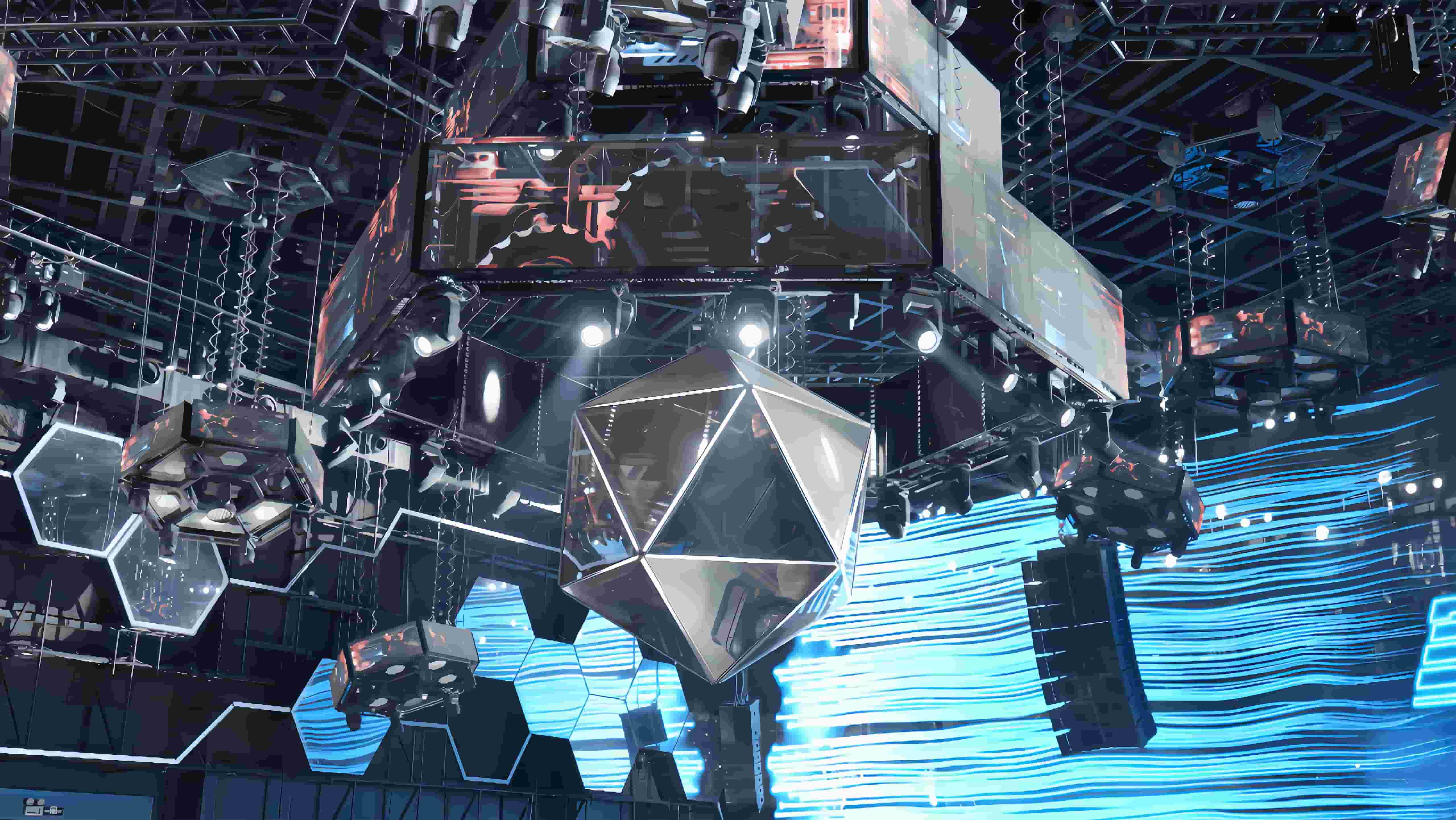

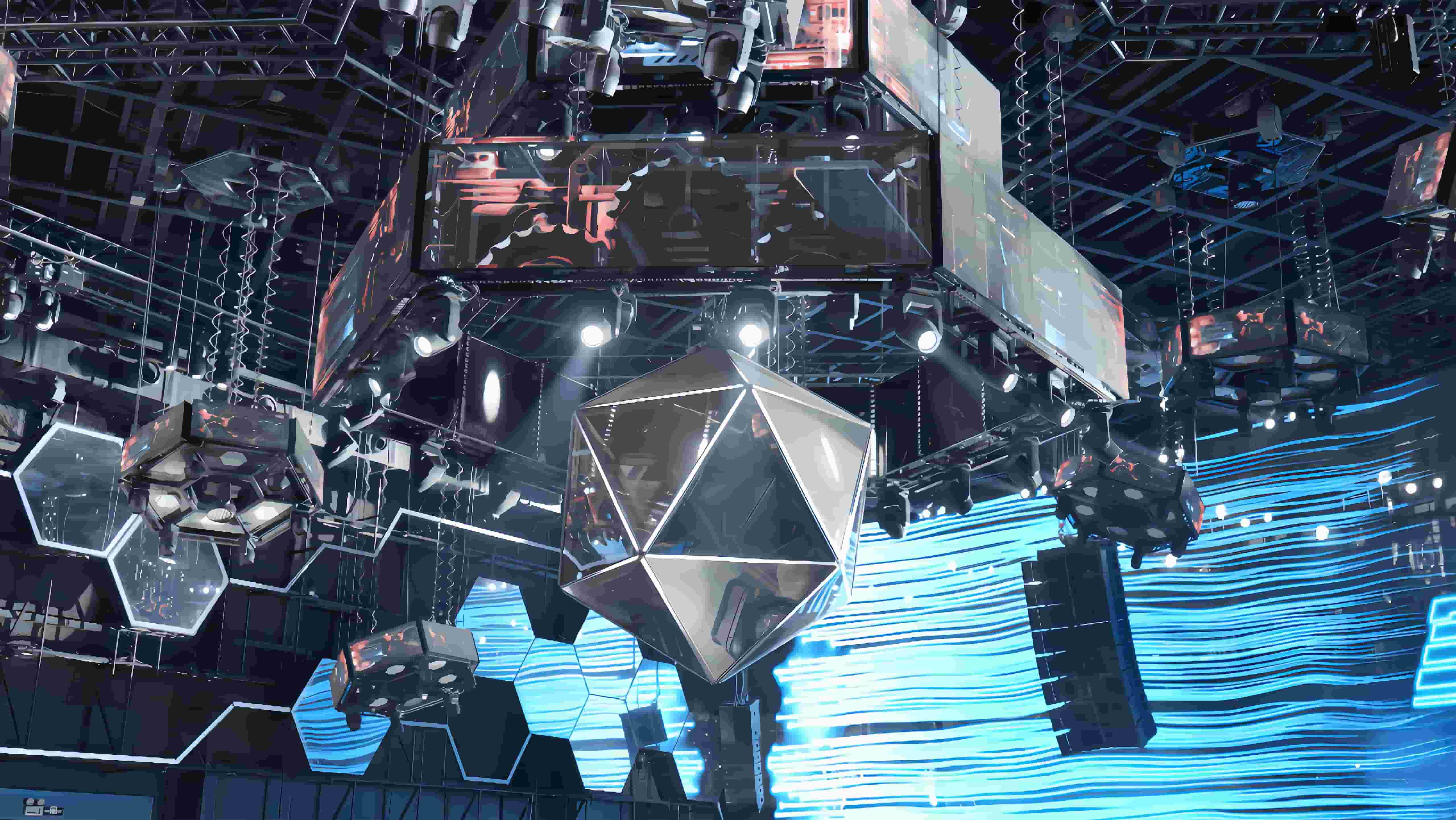

- Purpose: Designed for precise vertical lifting, frequent stops and starts, and accurate positioning (e.g. lifting lighting trusses, LED screens, or scenery elements).

- Safety Standards: Under “ASME B30.16 — Overhead Underhung and Stationary Hoists” and “EN 14492-2:2019”, electric hoists must include dual brakes, limit switches, and appropriate safety factors to prevent uncontrolled load drop.

- Product example: YZDITEC’s C1 Servo Hoist meets entertainment industry safety and performance requirements: it is certified to BGV-C1, CE marked, and conforms to EN 17206; it uses an absolute-encoder servo motor and SIL-class control architecture to provide precise, reliable operation.

3 2. What is a Winch?

- Definition: A pulling device centered on a rotating drum around which a steel cable or rope is wound. Winches are usually base-mounted (fixed to a floor or platform) and often use guide pulleys to redirect the cable.

- Purpose: Suited for long travel distances or horizontal pulls. Common applications include moving large scenery, trusses, bridges, or heavy screens across the stage.

- Safety Standards: ASME B30.7 — Winches defines drum design, rope layout, braking systems, and load testing requirements for safe winch operation.

- Product example: YZDITEC’s High-Speed Winch models can incorporate dual electromagnetic brakes, integrated load cells, servo drives with absolute encoders, and anti-tangle rope devices, delivering real-time load monitoring and a 12:1 safety factor on wire ropes.

3 3. Quick Comparison Table

|

Aspect

|

Electric Chain Hoist (ring-chain)

|

Winch (drum / wire-rope)

|

|

Typical use

|

Precise vertical lifting (short travel)

|

Long travel lifting / horizontal pull

|

|

Lifting medium

|

Load chain + chain wheel / gearbox

|

Steel cable wound on a drum

|

|

Installation

|

Hung on truss or mounted on a trolley

|

Fixed base or platform; uses pulleys

|

|

Advantages

|

High precision; good for frequent starts/stops; compact modular design

|

Long travel distance; high pulling force; suitable for continuous pulls

|

|

Drawbacks

|

Not suited for very long single-point travel without added trolley/track systems

|

Drum layering affects speed/tension; larger and heavier unit

|

4. Technical Comparison: Mechanical & Control Perspectives

4. 1. Lifting Medium: Chain vs Drum & Cable

- Hoist (ring-chain): Uses a steel load chain running over a chain wheel and gearbox.

- Winch (drum): Uses a cable wound on a drum; long runs are possible but drum layering changes effective diameter and thus line speed and tension, requiring compensation.

- Control note: Control systems often use encoder feedback, tension sensors, or constant-diameter drum designs to reduce drum-layer effects in high-precision winch applications.

- Stage Relevance: Short, precise lifts (e.g. adjusting a lighting truss or dropping small props) are best done with ring-chain hoists. Long-distance moves (e.g. sliding a large LED screen or shifting a stage bridge) are best done with winches or drum-type wire-rope hoists, often with position feedback (encoder) to compensate for drum wrap effects.

4.2. Power Transmission and Braking Systems

- Hoist: Typically uses gear-reduction drives and is fitted with dual brakes (main and emergency) plus upper/lower limit switches to meet fail-safe requirements (EN 14492-2 / ASME B30.16). High-end servo ring-chain hoists add absolute encoders, position memory after power loss, and closed-loop servo control to deliver millimeter-level repeatability and rapid response — features especially valuable for synchronized scenic motion and performer flying systems.

- Winch: Designed for drum braking and sustained duty; drums usually have individual brakes sized to withstand thermal loads during long pulls. ASME B30.7 requires appropriate brake and rope management design.

- Stage Relevance: Hoists suit cue-accurate, frequent stops; winches suit sustained pulls and long runs if drum effects are managed.

- Example — YZDITEC Electric Stage Hoist

Offers ±1 mm positioning accuracy, ultra-smooth motion (0.01 – 0.5 m/s), dual electromagnetic brakes, integrated load cell, 4-point limit switches, IP65 enclosure, and quiet operation (~ 68 dB) — a configuration trusted for performer-flying and precision scenic automation.

- Example — YZDITEC Heavy Duty Winch

Uses a servo-driven drum with dual electromagnetic brakes, real-time load monitoring, anti-sway motion algorithms, and redundant E-stop circuits — providing smooth heavy-load handling up to 1000 kg with ± 1 mm positioning.

These configurations illustrate how modern servo technology and dual-brake designs deliver greater holding power, safety compliance, and operator confidence on live event stages.

4. 3.

4. 3.

4. 3. Installation and Positioning

- Hoist: Hung on trusses or mounted on powered trolleys — ideal for touring due to compactness and standardized hanging points.

- Winch: Anchored to floor or fixed structures; direction changes via pulleys.

- Stage Relevance: Touring and temporary stages prefer chain hoists (lightweight, quick rigging). Large fixed theaters or heavy scenic moves often use winches (installed on stage floor or house grid, pulling loads over long spans).

- Integration note: For multi-axis scenic automation, servo hoists integrated into EtherCAT-based control environments enable synchronized cluster movement across multiple axes.

- YZ DITEC in practice—Advantage of Electric Lifting HoistYZDITEC’s servo-driven electric chain hoists, when paired with our EtherCAT-based Show Control Automation Console, deliver ultra-precise synchronized multi-axis motion—scalable up to 128 axes. Thanks to ±1 mm positioning accuracy, adjustable speed (0.01–0.5 m/s), absolute encoders with power-loss memory, and real-time load-cell feedback, multiple hoists can lift, tilt, rotate, or track LED walls, scenic bridges, and performer-flying rigs perfectly in sync across the stage.

The system’s plug-and-play EtherCAT integration plus Pando 3D simulation allows virtual pre-programming and near-instant setup—cutting on-site installation time by up to 50 percent—while maintaining BGV-C1, EN 17206, and SIL3-compliant safety for show-critical moves.

4. 4. Travel Length and Speed Characteristics

- Hoist: Best for short lifts (practical chain lengths in the meter to low-tens-of-meters range) with high positional accuracy; speeds are adjustable via VFDs or servo drives. Extended travel with ring-chain hoists is normally achieved by using trolley/track systems rather than drum reeving.

- Winch: Can provide very long travel distances limited by cable length and drum capacity; line speed and tension change with drum layering unless compensated.

- Stage Relevance: Millimeter-level accuracy favors servo-driven hoists; long-travel tasks favor winches with encoder/tension management.

4. 5. Capacity and Safety Factor

- Hoist: Ranges from a few hundred kilograms to tens of tons; entertainment ring-chain hoists typically cover 250–2000 kg for common stage use. “EN 14492-2” and “ASME B30.16” require redundant braking and limit devices on personnel-rated hoists. And according to “EN 818-7” (G80 hoist chains) and stage-rated standards such as “BGV-C1” and “EN 17206”, stage hoists for lifting loads above people are required to use fine-tolerance alloy steel chains with a minimum safety factor of 8:1, and often up to 10:1 depending on application.

- Winch: Also covers hundreds of kilograms up to multi-ton capacities; ASME B30.7 requires emergency braking and rope-management controls.

- Stage relevance: Only purpose-certified equipment should be used for personnel lifting; material hoists and non-certified winches must not be used for man-riding.

- Certification note: Devices certified to BGV-C1, EN 17206 and bearing CE marking indicate design, testing and documentation adequate for operation above people (i.e., allowed to run over performers/audience) when used according to the certificate scope.

- Example: YZDITEC chain hoists utilize Japan-made FEC G80 high-strength alloy-steel chains with a safety factor of 12, dual-brake design, overload-limiting clutch, and IP65 dust-/water-resistant housings, ensuring safer operation under show-critical conditions.

- Example: YZDITEC winches feature redundant braking, over-speed detection, and electronic load monitoring, providing high safety margins for heavy-duty scenic or stage lift operations.

5. Standards and Regulations (Must-Comply)

5.1 Electric Hoist / Lifting Hoist:

- “EN 14492-2:2019 — Cranes: Power Driven Winches and Hoists — Part 2: Power Driven Hoists” — design, brake and limiter requirements, safety factors, inspection/testing.

- “ASME B30.16 — Overhead Underhung and Stationary Hoists” — installation, maintenance, marking, safe operation.

- For entertainment/people-over scenarios, “EN 17206” and German entertainment guidance (historically “BGV-C1”, now integrated into “DGUV recommendations”) provide additional tests and operational requirements specific to stage use; CE conformity plus these references is commonly required to authorize operation above performers/audience.

5.2 Winch:

- “ASME B30.7 — Winches” — drum, rope arrangement, braking, testing and inspections.

- “EU machinery directive & CE conformity” apply to winches; check national stage rigging rules and venue certification requirements for operation over people.

5.3 Application Guidance:

- For EU/CE markets: verify “EN 14492-2” (hoist), “EN 17206” (stage equipment), and CE declaration; prefer devices with explicit entertainment-use certification for people-over applications.

- For Americas: follow ASME B30.16 for hoists and ASME B30.7 for winches.

- If the risk assessment requires high functional safety for the control layer, specify “SIL3” or equivalent safety integrity levels for redundancy and diagnostic coverage.

6. Stage Scenarios and Recommendations

- Touring / Temporary Stages: Use ring-chain servo hoists for compact, synchronized, low-noise, low-speed precision and fast rigging. For example, a certified C1 Servo Hoist (500 kg) provides dual electromagnetic brakes, integrated load cell, 4-point limit switches, IP65 protection, absolute encoders with position memory after power loss, and ±1 mm positioning — suitable for performer flying, synchronized LED wall lifts and automated scenic transitions.

- Large Scenic Moves (Long Travel): Use winches or drum-type wire-rope hoists with encoder feedback and tension management for long runs and heavy loads. High-performance winch families can provide servo control, dual brakes, integrated load monitoring and anti-tangle systems for reliable long-travel operations.

- Lifting Personnel / Special Effects: Use only certified man-riding systems with documented compliance; never substitute material hoists or non-personnel winches.

7. Five-Step Selection Process

- Assess conditions: motion direction (vertical, horizontal, combo), max load, travel distance, duty cycle. (frequency of use).

- Initial equipment choice: short travel & high-frequency& high-precision → ring-chain hoist (servo when low-speed precision matters); long travel/heavy& horizontal pull → winch or drum-type wire-rope hoist.

- Check standards: EU → EN 14492-2 and EN 17206 / CE; US/international projects → ASME B30.16 (hoist) / ASME B30.7(winch).

- Design redundancy and safety: dual brakes, limit switches, load monitoring; for people-over use require entertainment certifications(BGV-C1 / EN 17206) and consider SIL3 equivalent safety for control systems.

- Acceptance testing: no-load and full-load tests, verify limiters/brakes, record test reports and inspection schedule in procurement documentation.

8. Maintenance Tips and Common Issues

- Electric Hoist: Inspect load chain for wear/elongation, verify gearbox lubrication and backlash, check hooks and attachments, test limit switches and emergency stops. Emphasize gearbox and chain inspection specific to ring-chain hoists rather than drum/wire-rope checks.

- Winch: Inspect wire rope for broken wires, kinks, corrosion; ensure even spooling on drum; monitor brake temperature during long pulls.

- Inspection Schedule (recommendations):

- 3-Step Decision Method:Direction: Vertical lifting → prefer ring-chain hoist; horizontal/long pulls → prefer winch.

- Travel Distance: Short travel → hoist; long travel → winch

- Precision & Duty: High precision/high cycle → servo hoist; continuous heavy pulls → winch.

Require manufacturer documentation — CE declaration, EN 14492-2 / EN 17206 test reports, BGV-C1 (DGUV) evidence where applicable, ASME certificates, and any SIL3 functional safety statements — and include applicable standards and acceptance tests in the procurement contract.

9. Common Misconceptions (FAQ)

- “Are winches always cheaper than hoists?” No — not necessarily; high-capacity, multi-drum winches or custom long-travel systems can cost more than advanced entertainment hoists.

- “Can hoists do long travel?” Yes, with additional trolley/track systems, but this greatly increases complexity and cost; ring-chain hoists do not use drum reeving — extended travel is achieved mechanically.

- “Can I substitute a hoist for a winch or vice versa?” Generally each is built for its purpose under different standards. Never use material hoists or non-certified winches for personnel lifts.

10. Conclusion and Actionable Recommendations

- 3-Step Decision Method:Direction: Vertical lifting → prefer ring-chain hoist; horizontal/long pulls → prefer winch.

- Travel Distance: Short travel → hoist; long travel → winch

- Precision & Duty: High precision/high cycle → servo hoist; continuous heavy pulls → winch.

Require manufacturer documentation — CE declaration, EN 14492-2 / EN 17206 test reports, BGV-C1 (DGUV) evidence where applicable, ASME certificates, and any SIL3 functional safety statements — and include applicable standards and acceptance tests in the procurement contract.

For event production managers, stage engineers, and venue owners, a clear understanding of the differences between electric chain hoists and winches—along with careful evaluation of standards compliance, lifting medium, motion profiles, and maintenance support—ensures both creative freedom and uncompromised safety.

Selecting the right certified equipment and following disciplined maintenance keeps stage projects running smoothly and reliably, while YZDITEC’s EN 17206 / BGV-C1-certified, servo-controlled, precision-engineered hoists and winches deliver confidence in safety, accuracy, and seamless show integration worldwide.